What Is A Laser Engraver?

Initially, we talked about what is an engraver. We will shift our gaze toward the laser engraver. The idea of laser engraver is simple- you inscribe materials with a laser beam.

Materials That Can Be Engraved With Laser

You can’t inscribe any objects or materials on earth with a laser. The materials have to be laserable. However, materials that you can usually engrave with laser are- glass, metal, plastic, jewelry, leather, medical equipment, and fine arts.

Laser Etching

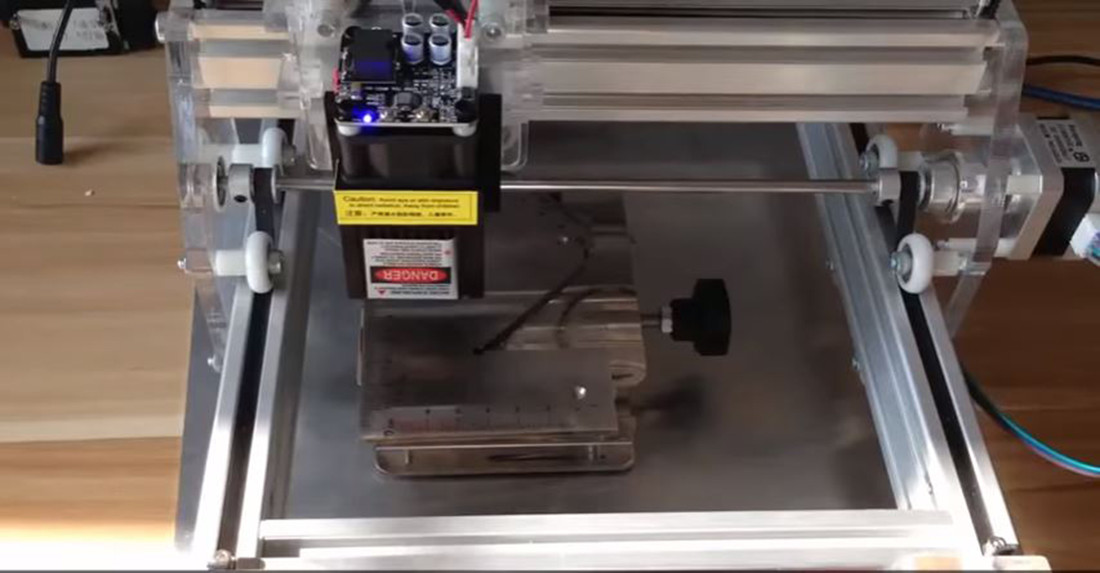

This is a sub-class of a laser engraver. This is mainly employed to etch or mark metals. A metal laser engraver can be found in various formations. The most popular one is the mini laser engraver.

Uses Of Metal Laser Engraver

There are some popular applications of a metal laser engraver. For example- barcodes, logos, serial numbers are usually inscribed by metal laser.

Again, there are some differences in lasers that you can use on metals. Furthermore, different sorts of metals require different kinds of lasers. Also, the uses of lasers vary depending on marks.

There is a CO2 laser and fiber laser. The CO2 laser is used when you want to mark metal without removing any metals. And, the fiber laser is used for engraving brass, copper, aluminum, nickel-plated materials, stainless steel, etc.

Upsides Of Metal Laser Engraver

This is a versatile technology. So, you can use this to mark metals and mark other materials as well. Still, you need to make sure the materials are suitable for laser engraving

A laser engraver is a safe technique since it doesn’t require any human touch. The beam with solely accomplish the job.

The quality of the results is also praiseworthy. Clearly, people use this technique for a reason! The precision of this technology is mind-blowing. It’s very satisfying to watch.

Another advantage of metal engraving is- it’s an environment-friendly technology. In addtion, this method has optimum efficiency. You will be able to mark materials in different depts.

What Is Laser Cutting?

Unlike engraving or making marks on materials, you directly cut materials with a laser. In other words, metal laser cutting means you slit through metals without touching it in any possible way. A laser cutting machine for metal is also known as a laser cutter.

Uses Of Laser Cutter

A metal laser cutting machine can be employed to cut materials like – carbon manganese steel, stainless steel, brass, aluminum, titanium.

Alongside these materials, you can use a metal laser cutter on thermoplastic, various non-metal, and wood as well.

Different Laser Cutter

Like laser engravers, there are mainly two types of laser cutters used in industrial sheets: CO2 laser cutter and fiber laser cutter.

Latest Laser Cutter Technology

The direct diode laser is the most recent laser technology. The specialty of this technology is several beams come out at once from a semi-conductor.

Upsides Of Laser Cutting Process

To start off, laser cutting is more flexible. You could cut metals in any kind of shape. Laser cutting is so smooth in nature that any sophisticated design can be developed by it. This means, precise of the laser cutting process is incredible.

A laser cutter is apt at repeating the same precision as many times as it requires. Also, it has an attribution of being amazingly fast as a cutting process.

Laser cutting is highly computerized. As a result, laser cutting stands out as the most efficient technique. The method doesn’t require any human contact, which makes it safer. Overall, the laser cutter is genuinely a productive method.

To Warp-up

Metal laser engraver and metals laser cutting are two crucial technologies in making designs. Making designs and art is so much easier these days with a laser engraver and lesser cutter. And, the usefulness of these technologies can be appropriately realized if you consider how difficult it is to curve design or make a slit in metal.